Ko ngā ārai-pahuka silicone he mea hanga i te silica hydrophobized e marara pai ana i roto i te wai silicone. Kātahi ka whakau te matū hua hei emulsion wai, hinu rānei. He tino whai hua ēnei ārai-pahuka nā te koretake o te matū, te kaha ahakoa he iti te kukū, me te kaha ki te horapa ki runga i te kiriata pahuka. Mena e tika ana, ka taea te whakakotahi me ētahi atu totoka hydrophobic me ngā wai hei whakapai ake i ō rātou āhuatanga tango-pahuka.

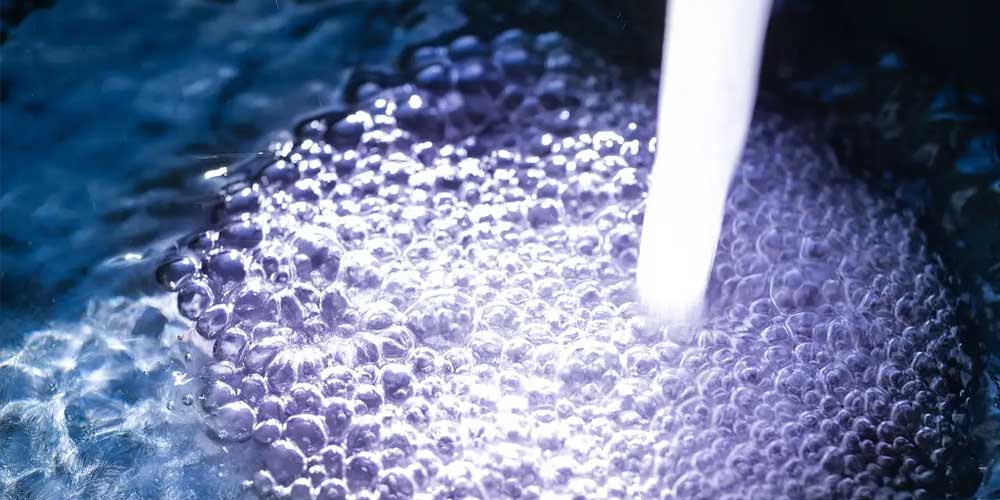

He pai ake ngā kaihoko ārai-huka silicone. Mā te wawahi i te taumahatanga o te mata ka whakakore i ngā mirumiru pahuka, ka hinga ai. Mā tēnei mahi ka tere te whakakore i te pahuka, ā, ka ārai hoki i te hanganga o te pahuka.

Ngā painga o te silicone defoamer

• He whānuitanga o ngā tono

Nā te hanganga matū motuhake o te hinu silicone, kāore e hototahi ki te wai, ki ngā matū rānei kei roto ngā rōpū polar, ki ngā warowaihā, ki ngā matū rauropi rānei kei roto ngā rōpū warowaihā. Nā te mea kāore e wairewa te hinu silicone i roto i te maha o ngā matū, he whānui ngā whakamahinga o te silicone dehumidifier. Kāore e taea te whakamahi mō ngā pūnaha wai dehumidifier anake, engari mō ngā pūnaha hinu dehumidifier anō hoki.

• Te iti o te kukū o te mata

Ko te kukū mata o te hinu silicone he 20-21 dynes/cm te tikanga, ā, he iti iho i te kukū mata o te wai (72 dynes/cm) me ngā wai pahuka whānui, ka pai ake te pānga whakahaere pahuka.

• He pai te pumau o te wera

Hei tauira, hei whakamahi i te hinu dimethyl silicone e whakamahia whānuitia ana, ka taea e tōna ātete pāmahana mō te wā roa te eke ki te 150°C, ā, ka taea e tōna ātete pāmahana mō te wā poto te eke ki runga ake i te 300°C, kia taea ai te whakamahi i ngā kaihoko whakakore huware silicone i roto i te whānuitanga o te pāmahana.

• He pai te pumau o ngā matū

He tino pumau te hinu silicone, ā, he uaua ki te tauhohe matū ki ētahi atu matū. Nō reira, mena he tika te whakaritenga, ka whakaaetia te whakamahi i ngā kaihoko whakakore huka silicone i roto i ngā pūnaha kei roto ngā waikawa, ngā kawakore, me ngā tote.

• Te koretake o te tinana

Kua whakamātauhia te kore paitini o te hinu silicone ki te tangata me ngā kararehe. Nō reira, ka taea te whakamahi haumaru i ngā whakakore huka silicone (me ngā emulsifier kore paitini e tika ana, me ētahi atu) ki te penupenu me te pepa, te tukatuka kai, te hauora, te rongoā me ngā mahi whakapaipai.

• He kaha ki te whakakore i te huka

Kāore e taea e ngā kaiwhakakore pahuka silicone te wawahi i te pahuka kāore e hiahiatia ana, engari ka ārai nui hoki i te pahuka me te aukati i te hanganga o te pahuka. He tino iti te horopeta, ā, kotahi miriona (1 ppm, 1 karamu/m3 rānei) o te taumaha o te rauemi pahuka ka taea te tāpiri hei whakaputa i te pānga whakakore pahuka. Ko tōna awhe noa ko te 1 ki te 100 ppm. Ehara i te mea he iti noa te utu, engari kāore e whakapoke i ngā rauemi e whakakorea ana.

E whakanuia ana ngā ārai-pahuka silicone mō tō rātou pumau, te hototahi ki ngā momo matū, me te whai huatanga i roto i ngā kukū iti. Heoi, he mea nui kia whakarite kia tutuki i ngā paerewa ture, kia tika hoki mō te whakamahinga motuhake kia kore ai e pā kino ki te kounga o te hua, ki te taiao rānei.

Wā tuku: 18 Paenga-whāwhā 2024